Research Paper Spotlight: Assessing the Purity of Pharmaceuticals Using QCLs

The original research paper highlighted below, "API Content and Blend Uniformity Using Quantum Cascade Laser Spectroscopy Coupled with Multivariate Analysis," can be found at the MDPI site: [external PDF link].

The original research paper highlighted below, "API Content and Blend Uniformity Using Quantum Cascade Laser Spectroscopy Coupled with Multivariate Analysis," can be found at the MDPI site: [external PDF link].

In the process of pharmaceutical manufacturing, it's essential to accurately measure the concentration of "active pharmaceutical ingredients." In this paper, Dr. Samuel P. Hernandez-Rivera at the University of Puerto Rico and his colleagues use quantum cascade lasers to analyze these chemicals. Below are some highlights of their process and findings.

Drugs that are manufactured in solid tablet, capsule, or powder forms are usually created by mixing active pharmaceutical agents with additional "excipient" ingredients. These excipients include fillers, binders, coloring agents, coatings, and other components.

From a quality control and safety standpoint, it is essential to determine whether the active pharmaceutical ingredients (APIs) are present in target concentrations. It is also important to determine whether the API-excipient mix is uniform.

Historically, manufacturers have used technologies such as chromatography and UV-Visible spectroscopy to analyze samples. Unfortunately, these techniques often require that samples be destroyed and processed in a lab.

Historically, manufacturers have used technologies such as chromatography and UV-Visible spectroscopy to analyze samples. Unfortunately, these techniques often require that samples be destroyed and processed in a lab.

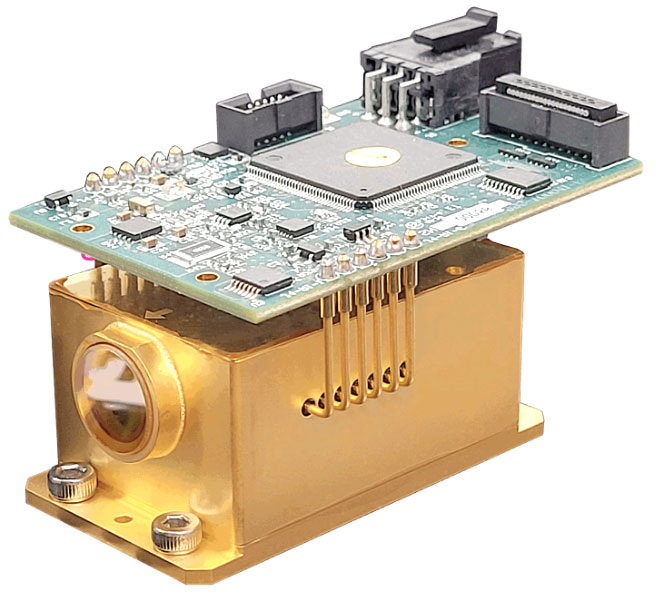

In this paper, Dr. Hernandez-Rivera and his team used quantum cascade lasers from Block Engineering to quickly scan pharmaceuticals from a distance of approximately 15 cm away. In as quickly as a half-second, they were able to capture an infrared spectrum showing the concentration of chemicals within a drug mix. This represents a excellent way to scan drugs in a manufacturing line, without touching the samples in any way.

The researchers began by obtaining a concentrated form of ibuprofen, which served as the target API. They then blended the ibuprofen with four common excipients, including lactose monohydrate (a sweetener), microcrystalline cellulose (a bulking agent), colloidal silicon dioxide (an adsorbent), and magnesium stearate (a flow agent). They mixed these excipients with the API in fourteen different concentrations in order to test detection.

Using a mid-infrared spectrometer powered by multiple quantum cascade lasers, the researchers scanned the mixtures at three wavelength ranges: 990 to 1111 cm-1, 1111 to 1178 cm-1, and 1178 to 1600 cm-1. Each of these scanning ranges required only a half-second to acquire a spectrum.

As an additional test, they measured the silicon dioxide excipient using both traditional FTIR spectroscopy and the new QCL system. Silicon dioxide is particularly difficult to analyze using FTIR spectroscopy, and tends to produce a great deal of "noise" in scans.

The researchers were able to clearly distinguish spectral signatures of low-API drug concentration blends compared to high-concentration blends. They were also able to measure degradation of the samples over a 60-day timeframe, with the changes possibly due to absorbed water vapor.

The researchers were able to clearly distinguish spectral signatures of low-API drug concentration blends compared to high-concentration blends. They were also able to measure degradation of the samples over a 60-day timeframe, with the changes possibly due to absorbed water vapor.

In addition, the QCL spectrometer produced signal-to-noise ratios for the silicon dioxide that were thirty times better than those of the FTIR. This is likely because of the high brightness of the quantum cascade laser source compared to a conventional FTIR Globar light source.

Block has worked with both researchers and manufacturers to improve pharmaceutical quality control. If you are interested in learning how QCLs can be used to measure APIs, please contact us for information.