LaserScan™: Standoff Detection of Trace and Bulk Solids, Liquids, and Films

Chemical and molecular signatures measured at a distance with high dynamic range

Block is preparing to launch the second generation of its award-winning LaserScan, a standoff chemical sensor that optically detects, identifies, images and maps substances on surfaces.

Block is preparing to launch the second generation of its award-winning LaserScan, a standoff chemical sensor that optically detects, identifies, images and maps substances on surfaces.

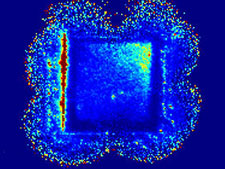

LaserScan provides chemical detection at a standoff distance of ½ to 5 meters away and can be customized for longer distances. Utilizing infrared hyperspectral imaging and absorption spectroscopy, LaserScan can identify trace substances and bulk materials. It can also detect and map sub-micron films based on their absorption characteristics.

At the heart of the sensor is a next-generation widely tunable Quantum Cascade Laser (QCL), which gives LaserScan sensitivities that are orders of magnitude greater than alternative spectroscopy sensors such as Raman or Fourier Transform Infrared (FTIR).

LaserScan operates between 5.4-12.8 µm (780-1890 cm-1) where most substances of concern have unique identifying signatures.

Mode of Operation and Library

The sensor can be configured in benchtop, tripod, or gantry-mounted configurations (and soon robot-mounted and hand-held instruments), which provide high-quality reflectance spectra from interrogated materials and surfaces. LaserScan then analyzes these spectra against preconfigured libraries. This allows the sensor to adapt to a variety of applications (and quickly address emerging threats) by tailoring the library to relevant substances.

Comparison to FTIR and Raman

LaserScan directs more energy at a specific wavelength to the sample than an FTIR spectrometer can. This provides higher sensitivity and higher power density measurements, especially from diffuse and highly absorbing materials and substrates.

Other advantages over FTIR include portability, ruggedness, fast analysis in seconds, and the ability to work at a safe distance. While FTIR can perform passive standoff to detect large gas clouds, FTIRs cannot offer active standoff capabilities. This makes it difficult to quickly scan surfaces and avoid contamination.

Raman systems require near-contact with the surface to be tested, and often use a powerful, non-eye-safe laser beam. Raman is also not sensitive enough to detect trace materials. The LaserScan's long standoff distance and large, eye-safe, collimated beam allow for faster surface scanning and easier field operation. Furthermore, LaserScan does not create a fire or detonation hazard with darkly colored materials and avoids sample degradation or thermal damage.

LaserScan is designed for applications in a wide variety of industries including:

Security and Defense operations to attain, establish, and obtain standoff detection for trace and bulk threats

Security and Defense operations to attain, establish, and obtain standoff detection for trace and bulk threats

- Explosives, both military grade and homemade, potentially used in vehicle-borne or person-borne attacks

- Chemical warfare agents, including non-traditional agents such as the Novichok family of nerve agents

- Pharmaceutical-based agents and illegal drugs such as fentanyl

Contaminants: detection of unwanted contaminants

- Silicone Detection: silicone is present in a wide variety of industrial processes, but it is problematic when it gets deposited on a surface that is to be subsequently coated.

- Semi-conductor processing equipment cleanliness

Geology and Mining

- Identifying rocks and minerals

- Soil analysis

Coatings: detection of coatings to ensure proper application (QA/QC)

- Coated medical devices to confirm that the coating is complete as part of the quality control process

- Industrial processes to coat web-based materials

- Protective coatings to prevent chemical degradation, such as rust and corrosion inhibitors

- Coatings to prevent surface adhesion and to reduce friction, such as lubrication films and release agents

- Coatings to promote adhesion for the bonding of surfaces, such as adhesive layer or intermediate layers

- Decorative coatings to provide protection and to promote an attractive finish, such as a painted surface

- Functional coatings applied in a hazardous environment, such as an insulating surface in a high voltage

- Metal conversion coatings such as anodization (e.g., aluminum, titanium, zinc, magnesium, niobium, zirconium), reactions with various phosphate compounds, and electroceramic and nanoceramic techniques

- Protective safety coatings such as those used in the food industry to coat cans

Curing Monitoring

- Curing or drying of decorative/protective paints such as in the automotive industry, where multiple layers of paint are applied and where the appearance of the final finish is critical for the sales value of the manufactured product

- Adhesive curing such as urethanes (and urethane pre-polymers), moisture cured cyanoacrylates ("Super Glue"), epoxy resins, and silicones

Block has delivered advanced prototypes of the LaserScan to the Department of Defense and the Department of Homeland Security for detection of explosives and chemical warfare agents. However, each commercial application may require custom algorithms or spectral pre- or post- processing. Block's engineers are adept at working with with customers to tailor or customize LaserScan to their unique requirements.

Contact us to discuss how the LaserScan can help with your application needs. Block's award-winning development team would be happy to discuss how our design services can help you reach your goals.